When you use our CEREC CAD/CAM system consignment services, you’ll enjoy the benefits of a stress-free transaction with minimal effort and maximum reward. Call 87 to speak with a CAD CAM Pro THE NEW V34 FEATURING: SMOOTH CUTTING QUALITY Simulation optimized to improve the look of cuts along the X Y Plane when using bullnose mill tools. As consequence a 2.5D CAM application can convert 2D outlines to 3D pockets. We can create thorough and professional CEREC machine listings that are sure to grab the attention of dentists looking for an affordable used CEREC system for their dental practice. As consequence they can be cut with a 3-Axis CNC machine. The usage of developed CAD & CAM system could design and manufacture the crowns and needed fillings, doctors use the software program CAD system to.

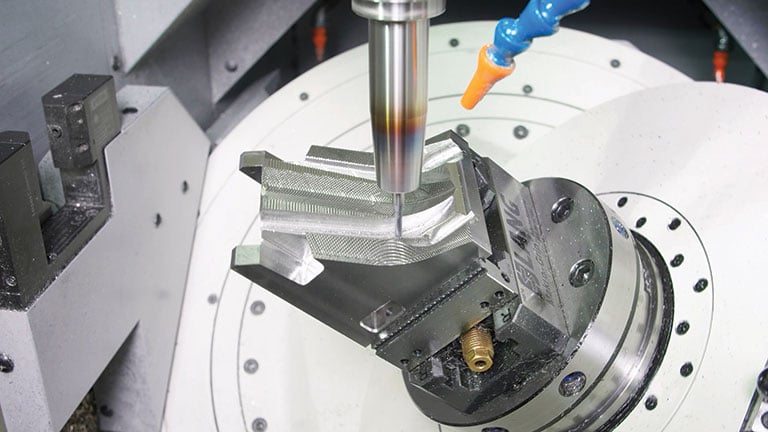

Image-comparison grip-lines arrow-top-right zip arrow-right video minus arrow-back text shop twitter file home quick-order arrow-left youtube search arrow-down check all filter site_references image Slice 1 zoom 🎬 icons / _ icon size / _ download-queueĬhevron-down arrow-right picture pdf podcast exe plus hotline close xxx-1 burger clipboard linked-in ppt Artboard 🎬 icons / _ icon size / _ download-queue_addĬreated by potrace 1. 2.5D is a term used in the CAD-CAM-CNC workflow to describe parts that comply to the following restrictions: All shapes are orthogonal exrtrusions of 2 D outline. CAM software (US site) uses the models and assemblies created in CAD software, like Fusion 360, to generate toolpaths that drive machine tools to turn designs into physical parts.

0 kommentar(er)

0 kommentar(er)